According to the International Energy Agency, more than 51% of failures in electric motors are caused by bearings. One of the root causes of the bearing problems is unbalancing, which needs to be checked continuously to avoid unexpected failures.

If we say the advancement in the current era is the greatest result of the rotating machines, it will not be wrong, and every rotating machine has got bearings and the bearings are “parts that support object’s rotation”. They support the shaft that rotates inside the machinery. Bearing is an essential part of every motor and generator. Bearing shape and size depends upon the nature of the job. For instance, ball bearings used in small motors need only lubrication for their working operation and no need for regular maintenance. But when the point comes to the big generators and machines where massive static bearings must have coated with white metal, having small holes to allow lube oil for lifting and lubrication purposes.

Contents

Bearings, Weak Side of Motors and Generators

The case of generators specially installed for baseload operations, which range from a few megawatts to hundreds of megawatt, has sophisticated bearings to meet robust requirements. For large bearings, especially generator bearings, there is a thin layer of material called “white metal” placed at the inner side on which the rotor used to be rolled / spin. The main usage reason for the white metal is to replace easily the layer in case of any wear and tear. This solution is greater than changing bearings. As it is well known that baseload generator needs to work 24/7, even for months continuously in such a scenario, wear and tear may happen in bearings. Besides, the bearings get easily damaged with improper lubrication, contamination, misalignment, corrosion, etc. When we looked at all of the factors that cause bearing failure, the bearings are the key component of the generators/motors, especially if we need smooth rotation and high-efficiency requirements.

May be Interested: Motor Condition Monitoring

Artesis e-MCM

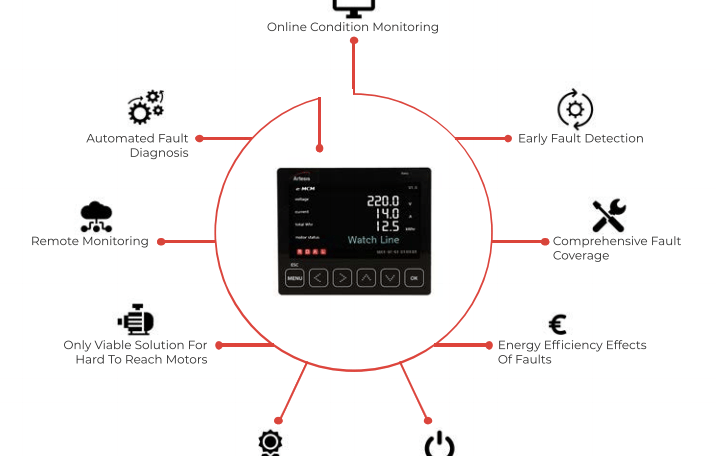

Artesis’s unique patented technology uses a model-based current and voltage approach to detect a wide variety of faults in electric motors. This model-based approach works on the principle that the current drawn by an electric motor is affected not only by the applied voltage but also by the behavior of the motor and driven equipment

e-MCM monitors your rotating equipment continuously, constantly taking measurements and comparing them with the digital twin it created during the self-learning process. Unlike conventional online systems, its unique machine learning algorithm allows it to recognize normal operation in a wide range of conditions, such as different speeds or loads – allowing tight control without false alarms. If e-MCM identifies a new operating state not experienced during the self-learning phase, it gives you the option of including this state in all future monitoring.

May be Interest: Predictive Maintenance Software

Artesis e-MCM Fault Coverage

- Loose foundation/ components

- Mechanical unbalance

- Misalignment

- Transmission faults

- Driven equipment faults

- Gearbox, belt, coupling

- Bearing, stator, and rotor faults

- Internal and external electrical faults

Therefore; bearing fault condition monitoring is equally important than any other considerations for reliable, safe and efficient operation of motor or generator.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ