500+ Global Brands Run on Artesis

About Us

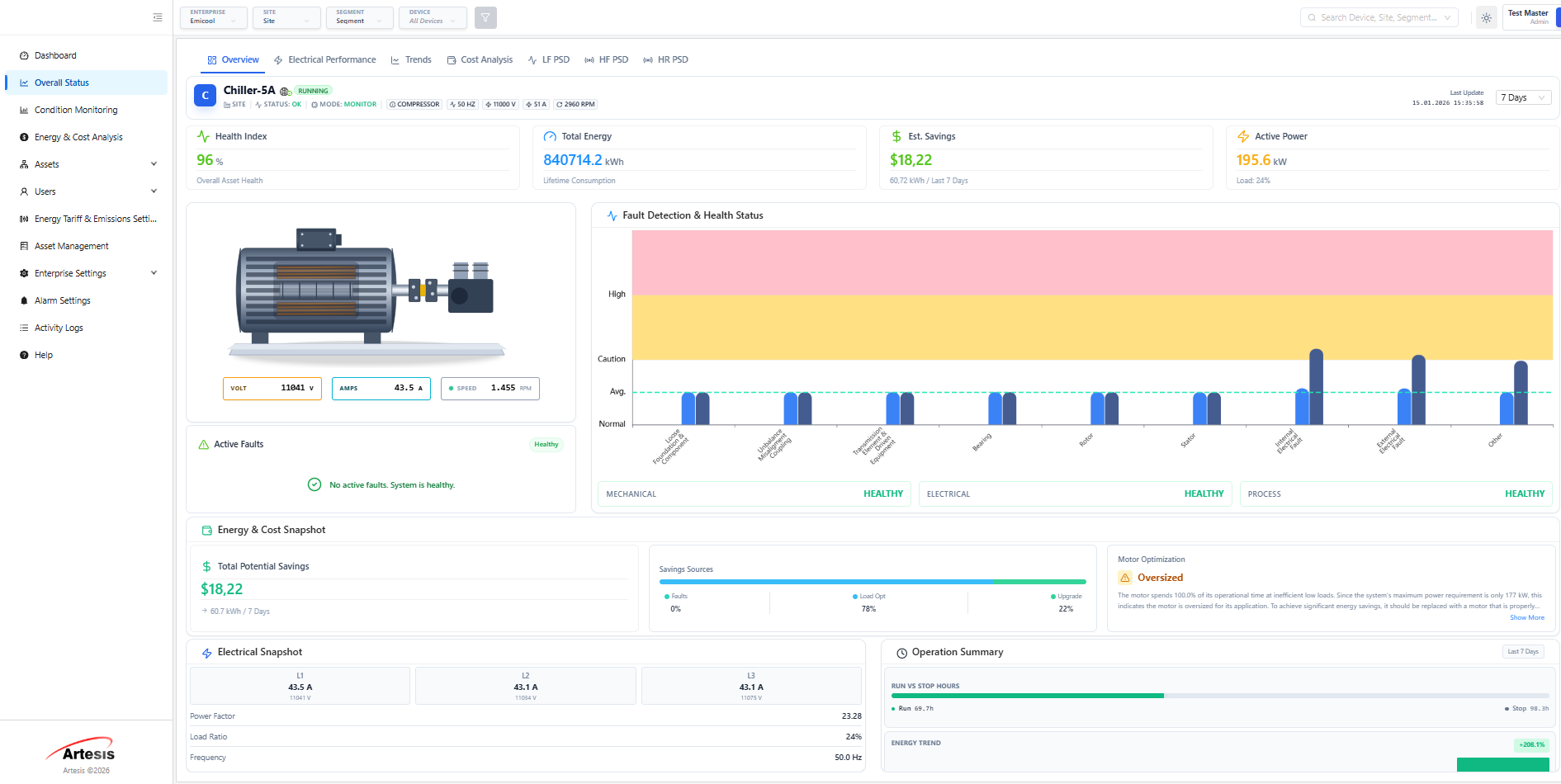

Optimizing Asset Performance with Smart Monitoring

Artesis empowers industries with advanced solutions to optimize equipment performance and prevent costly downtime.

Using cutting-edge machine learning and real-time analytics, our system provides early detection of faults and actionable insights, ensuring the reliability and efficiency of your critical assets.

25+ Years of Proven Success

Predictive Maintenance Powered by AI

Sensorless, Scalable Solutions

0+

Years Experience

0k

Satisfied Clients

Pump

e-MCM

Motor

Artesis Video Showcase

Listen to Artesis from our VP at WEFTEC 2024, presented by Pumps & Systems Magazine.

Artesis: Empowering Industrial Excellence Through Advanced Solutions

Water

Water

Oil & Gas

Oil & Gas

Automotive

Focused on innovation

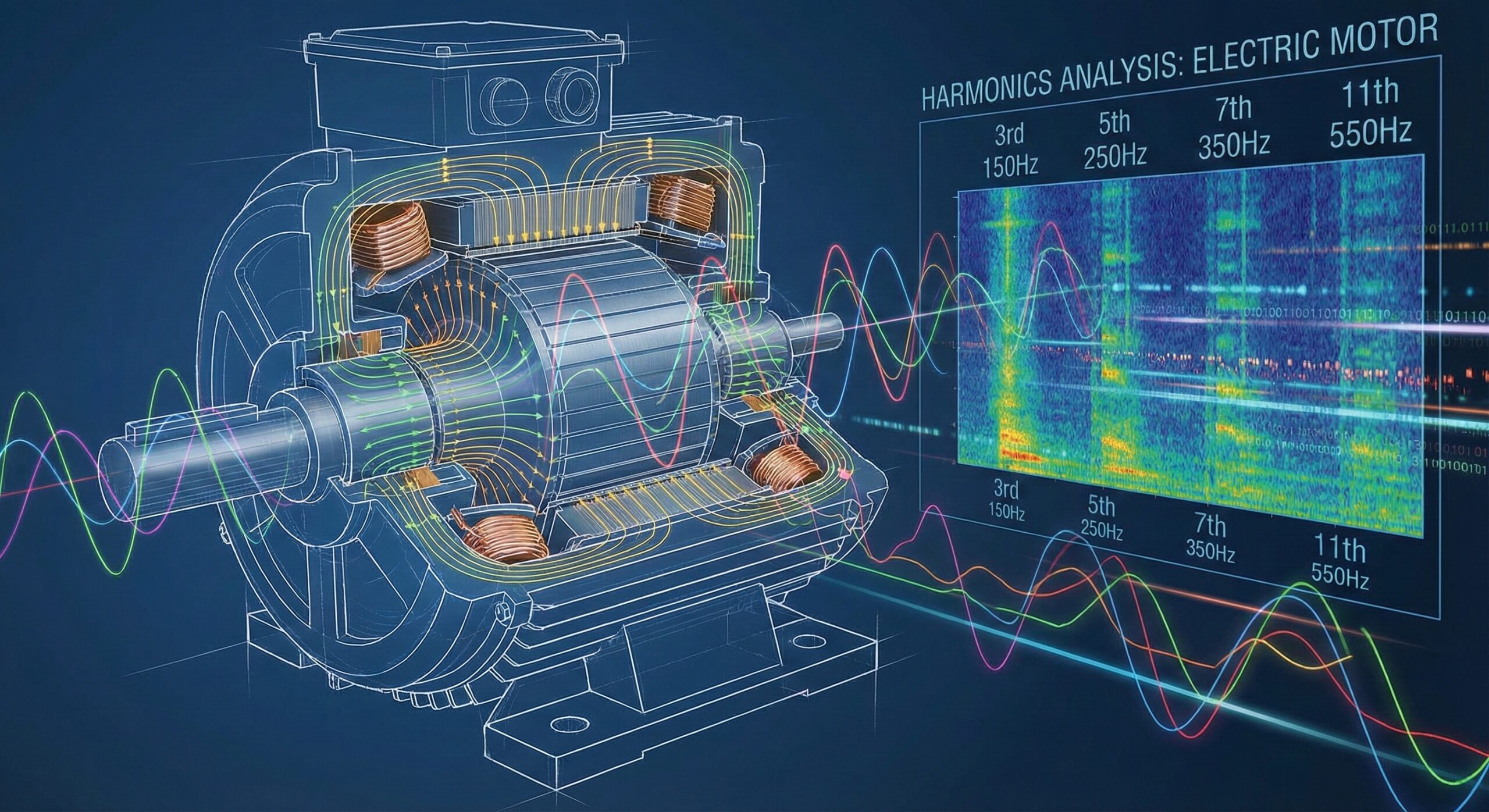

Revolutionizing Maintenance with Artesis e-MCM

The Future of Predictive Maintenance

Artesis e-MCM uses advanced signal processing and machine learning to continuously monitor motor performance, detecting faults up to 6 months before they cause disruptions. This proactive approach ensures the highest level of operational reliability.

Our Projects

Driving Maintenance Success Across the Globe

Installed in

0+

Facilities Across 50+ Countries

0%

Reduction in Unplanned Downtime

0%

Improvement in Energy Efficiency with Optimized Asset Performance

Freedom to Customize Your Maintenance Technology Stack

At Artesis, we empower you to take control of your condition monitoring and predictive maintenance strategies with our open ecosystem. Seamlessly integrate your preferred tools and systems to create customized solutions. Explore our extensive network of device, software, and AI partners, along with a robust library of pre-built connectors for effortless integration and enhanced operational efficiency.

What News Do We Have Today, Latest Blog

Harmonic distortion is often ignored as a mere “power quality” nuance,..

Spotting Archimedes screw pump failures early can protect your facility from..

AI predictive maintenance has revolutionized industrial operations with remarkable results. Recent data..

Industries have to re-evaluate and re-interpret their maintenance and production processes..

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ