Manufacturing is an ever-evolving industry, with new technologies and trends always emerging. In 2023, we can expect to see several significant developments that will shape the way manufacturing is done.

Keep reading to learn more about the ten trends that will dominate manufacturing in 2023.

Contents

- 0.1 Labor Retention

- 0.2 Employees Focusing on Work-Life Balance

- 0.3 Product as a Service Becomes More Widespread

- 0.4 The Internet of Things is Still Relevant

- 0.5 Next-Generation Predictive Maintenance

- 0.6 ERP Systems Receive a Makeover

- 1 Top Manufacturing Trends for 2023

- 1.1 Labor Retention

- 1.2 Employees Focusing on Work-Life Balance

- 1.3 Product as a Service Becomes More Widespread

- 1.4 The Internet of Things is Still Relevant

- 1.5 Next-Generation Predictive Maintenance

- 1.6 ERP Systems Receive a Makeover

- 1.7 Big Data Grows

- 1.8 Digital Twins Increase Efficiency

- 1.9 Changes to How Supply Chain Issues are Handled

- 1.10 Renewed Interest in Near-Sourcing & Reshoring

Labor Retention

The Great Resignation refers to the widespread sense of disillusionment and dissatisfaction among workers in many countries. This has been driven by factors such as stagnant wages, job insecurity, and a lack of opportunities for advancement. In 2023, these issues will likely continue to affect workers in many industries, including manufacturing. This could lead to increased absenteeism, turnover, and other forms of job dissatisfaction, which could negatively impact the productivity and efficiency of manufacturing businesses.

To address these issues, manufacturers must focus on creating a positive and supportive work environment, offering competitive wages and benefits, and providing career growth and development opportunities.

Employees Focusing on Work-Life Balance

There has been a growing emphasis on work-life balance among employees in recent years. This trend will likely continue in 2023, particularly in the manufacturing industry. To address this, manufacturers must create a supportive work environment and provide resources to help employees manage their work-life balance. By prioritizing work-life balance, manufacturers can improve employee satisfaction and retention and boost productivity and performance.

More Interested:Avoiding The Challenges Of Predictive Maintenance

Product as a Service Becomes More Widespread

Product as a Service (PaaS) is a business model in which a manufacturer provides a product on a subscription basis rather than selling it outright. In 2023, PaaS will likely become more widespread in the manufacturing industry as businesses recognize its benefits, such as building long-term relationships with customers and generating recurring revenue. PaaS can also help manufacturers to differentiate themselves from competitors by offering unique and value-added services.

The Internet of Things is Still Relevant

It’s expected that the Internet of Things (IoT) is set to continue playing a crucial role in the manufacturing industry. The IoT allows manufacturers to collect and analyze data, which can be used to optimize operations and improve efficiency. The IoT can also support predictive maintenance, helping manufacturers to reduce downtime and improve reliability. By adopting the IoT, manufacturers can gain a competitive advantage and improve their bottom line.

Next-Generation Predictive Maintenance

Next-generation predictive maintenance is a cutting-edge approach to maintaining equipment and machinery. This technology uses advanced data analytics and machine learning algorithms to predict when equipment is likely to fail, allowing maintenance to be scheduled in advance. This can help manufacturers to reduce downtime and improve the reliability of their operations.

Additionally, predictive maintenance can provide valuable insights into the overall health of equipment and systems, allowing manufacturers to make better-informed decisions about their operations. Overall, this technology is a powerful tool that can help manufacturers to stay ahead of potential problems and keep their operations running smoothly.

ERP Systems Receive a Makeover

ERP systems are receiving a makeover in 2023, with new technologies and approaches being developed to improve their effectiveness. These changes are driven by the need to better support the unique requirements of manufacturers, as well as to provide greater flexibility and scalability.

For example, many manufacturers are now looking to adopt cloud-based ERP systems, which can give access to enterprise-level functionality without needing expensive on-premises infrastructure. Additionally, manufacturers are increasingly looking to integrate their ERP systems with other technologies, such as the Internet of Things and artificial intelligence, to provide more significant insights and improve decision-making.

More Interested:5 Key Advantages Of Condition Monitoring In Belt Systems

Top Manufacturing Trends for 2023

Manufacturing is an ever-evolving industry, with new technologies and trends always emerging. In 2023, we can expect to see several significant developments that will shape the way manufacturing is done.

Keep reading to learn more about the ten trends that will dominate manufacturing in 2023.

Labor Retention

The Great Resignation refers to the widespread sense of disillusionment and dissatisfaction among workers in many countries. This has been driven by factors such as stagnant wages, job insecurity, and a lack of opportunities for advancement. In 2023, these issues will likely continue to affect workers in many industries, including manufacturing. This could lead to increased absenteeism, turnover, and other forms of job dissatisfaction, which could negatively impact the productivity and efficiency of manufacturing businesses.

To address these issues, manufacturers must focus on creating a positive and supportive work environment, offering competitive wages and benefits, and providing career growth and development opportunities.

Employees Focusing on Work-Life Balance

There has been a growing emphasis on work-life balance among employees in recent years. This trend will likely continue in 2023, particularly in the manufacturing industry. To address this, manufacturers must create a supportive work environment and provide resources to help employees manage their work-life balance. By prioritizing work-life balance, manufacturers can improve employee satisfaction and retention and boost productivity and performance.

More Interested:Avoiding The Challenges Of Predictive Maintenance

Product as a Service Becomes More Widespread

Product as a Service (PaaS) is a business model in which a manufacturer provides a product on a subscription basis rather than selling it outright. In 2023, PaaS will likely become more widespread in the manufacturing industry as businesses recognize its benefits, such as building long-term relationships with customers and generating recurring revenue. PaaS can also help manufacturers to differentiate themselves from competitors by offering unique and value-added services.

The Internet of Things is Still Relevant

It’s expected that the Internet of Things (IoT) is set to continue playing a crucial role in the manufacturing industry. The IoT allows manufacturers to collect and analyze data, which can be used to optimize operations and improve efficiency. The IoT can also support predictive maintenance, helping manufacturers to reduce downtime and improve reliability. By adopting the IoT, manufacturers can gain a competitive advantage and improve their bottom line.

Next-Generation Predictive Maintenance

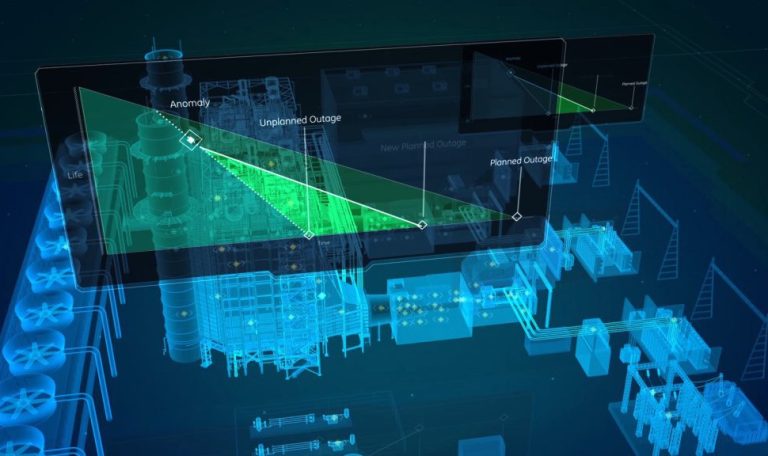

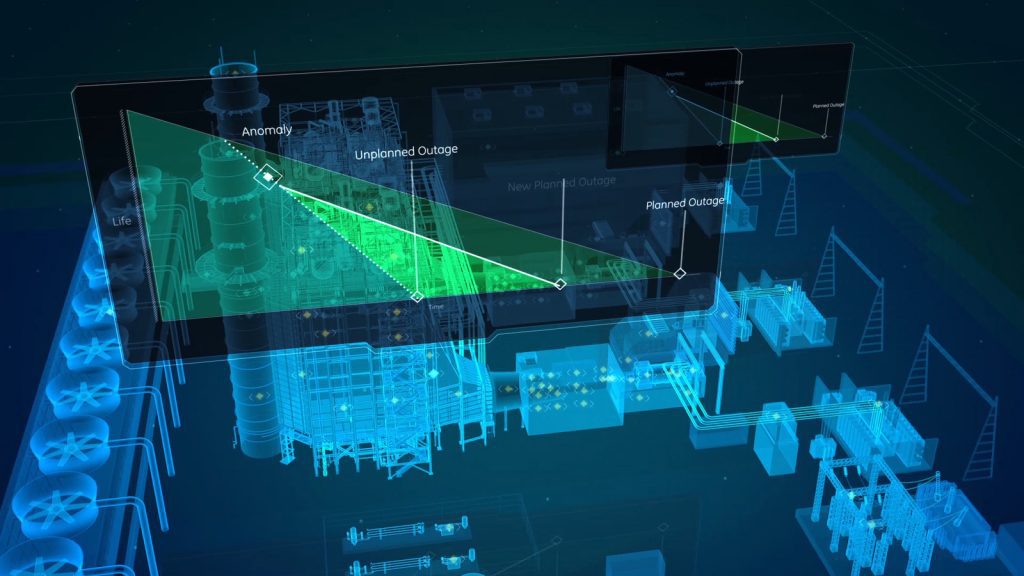

Next-generation predictive maintenance is a cutting-edge approach to maintaining equipment and machinery. This technology uses advanced data analytics and machine learning algorithms to predict when equipment is likely to fail, allowing maintenance to be scheduled in advance. This can help manufacturers to reduce downtime and improve the reliability of their operations.

Additionally, predictive maintenance can provide valuable insights into the overall health of equipment and systems, allowing manufacturers to make better-informed decisions about their operations. Overall, this technology is a powerful tool that can help manufacturers to stay ahead of potential problems and keep their operations running smoothly.

ERP Systems Receive a Makeover

ERP systems are receiving a makeover in 2023, with new technologies and approaches being developed to improve their effectiveness. These changes are driven by the need to better support the unique requirements of manufacturers, as well as to provide greater flexibility and scalability.

For example, many manufacturers are now looking to adopt cloud-based ERP systems, which can give access to enterprise-level functionality without needing expensive on-premises infrastructure. Additionally, manufacturers are increasingly looking to integrate their ERP systems with other technologies, such as the Internet of Things and artificial intelligence, to provide more significant insights and improve decision-making.

More Interested:5 Key Advantages Of Condition Monitoring In Belt Systems

Big Data Grows

In 2023, big data is set to continue growing in importance in the manufacturing industry. Manufacturers can gain valuable insights and make better-informed decisions by collecting and analyzing data from sensors, machines, and production lines. Big data can also support predictive maintenance, allowing manufacturers to reduce downtime and improve the reliability of their operations.

Digital Twins Increase Efficiency

Digital twins are virtual replicas of physical equipment, which allow manufacturers to monitor and simulate performance. Most experts feel it’s likely that their use will increase in the manufacturing industry. Digital twins can be used to identify potential problems before they occur, reducing downtime and improving efficiency. They can also support predictive maintenance and provide valuable insights into the health of equipment and systems. By leveraging digital twins, manufacturers can improve their operations and gain a competitive advantage.

Changes to How Supply Chain Issues are Handled

There are also likely to be significant changes in the way that supply chain issues are handled in the manufacturing industry. This trend is being driven by the need for greater flexibility and agility in supply chain management, as well as the increasing complexity of global supply chains. To address these challenges, manufacturers are likely to adopt new technologies and approaches, such as the use of advanced analytics and artificial intelligence, to improve their supply chain operations. Additionally, manufacturers are likely to focus on building more resilient and sustainable supply chains by reducing their dependence on a single supply source and increasing their use of local suppliers.

Renewed Interest in Near-Sourcing & Reshoring

Finally, there is likely to be a renewed interest in near-sourcing and reshoring in the manufacturing industry. This trend is being driven by concerns about the sustainability and resilience of global supply chains, as well as the need for greater flexibility and agility. As a result, manufacturers are likely to focus on building stronger relationships with local suppliers and increasing their use of near-sourcing and reshoring. This will enable them to reduce their dependence on a single source of supply and improve their ability to respond to changes in demand.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ