There is no denying that digitalizing predictive maintenance has many benefits, and one such advantage is the improvement of asset management. After all, digital technologies allow enterprises to achieve operational excellence goals by providing a much more cost-effective and broader use of predictive maintenance systems. In addition to cost-effectiveness use, predictive maintenance also utilizes analysis of data and acquisition for asset management and minimizing downtime and expenditure.

Contents

How Digitalizing Predictive Maintenance Help Improve Asset Management

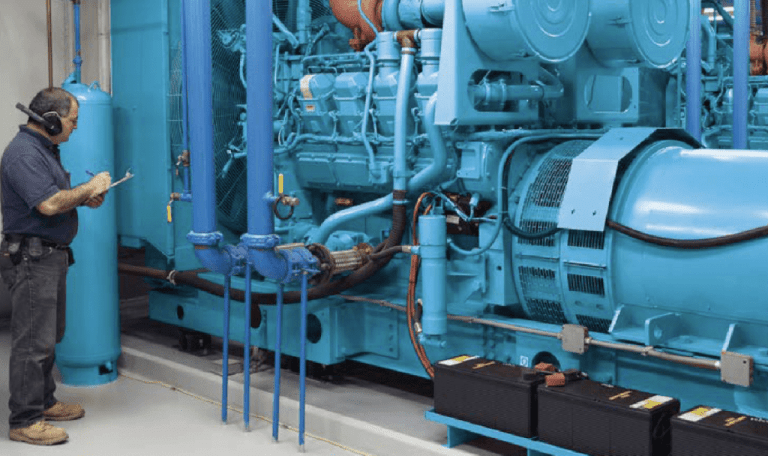

Currently, operational excellence depends on extensive manual effort and a dynamic change in the composition of engineering and maintenance staff. Managing the entire portfolio of assets requires a substantial investment in human resources, both in-house and from external suppliers.

In addition, the ecosystem of equipment and systems required for maintaining the equipment often exceeds the capabilities of individual organizations, particularly during outages and emergencies. In response to these challenges, many companies have established effective asset management strategies. Predictive maintenance systems are one such system. These aim to improve the identification of problems, maintenance schedules, and maintenance costs.

Operational Excellence and Asset Management Are Important For Increasing Productivity

Predictive maintenance helps to improve productivity; productivity leads to increased sales, and sales generate profits. Predictive maintenance helps to identify potential maintenance needs at an early stage. This allows for maintenance planning which reduces wasted costs and downtime.

A more efficient and cost-effective decision making in predictive maintenance and asset management leads to greater efficiency. More efficient planning allows maintenance costs to be reduced and savings passed on to customers. This allows for higher profits and greater value for money to be generated.

Asset Maintenance and Asset Management With IIoT

The IIoT is one of the top driving forces for asset management in the industrial sector. One cannot deny the fact that asset management plays an integral role in any manufacturing operation. The IIoT ensures that the operation’s productivity, efficiency, and safety will continue to meet the expectations of the management and the workers.

Many manufacturing companies in the industrial sector consider asset management a requirement. Although these companies are used to keeping up to date with the ever-changing needs of consumers and the constantly rising cost of operations, they are still eager to improve their level of asset efficiency in order to achieve their objectives. As mentioned in the introduction, predictive maintenance and asset management are the two primary industries driving IIoT.

Digitalization of Predictive Maintenance

Today, there is a growing market for digital technologies across the asset lifecycle. Digitalization has the potential to take many existing service scenarios to the next level, transforming a number of the core aspects of asset management. These new methods of data acquisition are fast becoming widely used across all industries. Just as digital technologies have introduced smart homes, smart businesses are set to follow. For example, mobile apps could provide maintenance personnel with real-time maintenance information. If issues are detected, they could be addressed before they affect the productivity of the equipment, reducing downtime and related costs.

The Bottom Line

In order to make asset management much more effective, it is imperative for facilities and industrial plants to shift asset maintenance from outdated preventive maintenance to predictive maintenance.

Asset management takes up a significant amount of time and energy for businesses. To get the most value from it, organizations need to embrace and make the best of predictive maintenance. We recommend looking at all the options available before making any decision and look for a software solution such as predictive maintenance that provides an intuitive interface with the same high levels of support you would expect from your business.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ