There is absolutely no denying the fact that condition-based maintenance (CBM) is playing a pivotal role in revolutionizing one important thing. Any guesses? Well, it is reshaping how industries manage equipment health by shifting from reactive or calendar-based approaches to data-driven strategies. And now industries have started to realize that monitoring real-time asset performance can predict failures, reduce downtime, and optimize maintenance costs.

So, if you are one of the businesses trying to embrace condition-based maintenance, this guide walks you through five essential steps to implement CBM effectively.

Contents

Understanding Condition-Based Maintenance

Simply put, one can explain condition-based maintenance as a proactive strategy that uses real-time data from equipment sensors to determine when maintenance is needed. Now it’s worth mentioning that CMB is not like your typical reactive maintenance (fixing assets after they fail) or preventive maintenance (scheduled regardless of actual condition). Oh no, CBM focuses on the actual state of an asset. What this means is that CMB analyzes parameters like vibration, temperature, or energy consumption so that the relevant teams can address issues before they escalate. This significantly helps minimize unplanned downtime and extends asset lifespans.

The benefits of condition-based maintenance are clear as a daylight, but the success of gaining those advantages hinges a lot on proper implementation. And this is where you have to follow five crucial steps to implementing condition-based maintenance:

Step 1: Choose the Right Assets

We cannot emphasize on this point enough: not all equipment is suitable for condition-based monitoring. That said, it is imperative you prioritize assets based on:

- Criticality: Determine beforehand how essential is the asset to your operations.

- Cost of failure: In case of a break down, what are the financial, safety, or production impacts?

- Accessibility: Is it possible to install sensors without disrupting workflows?

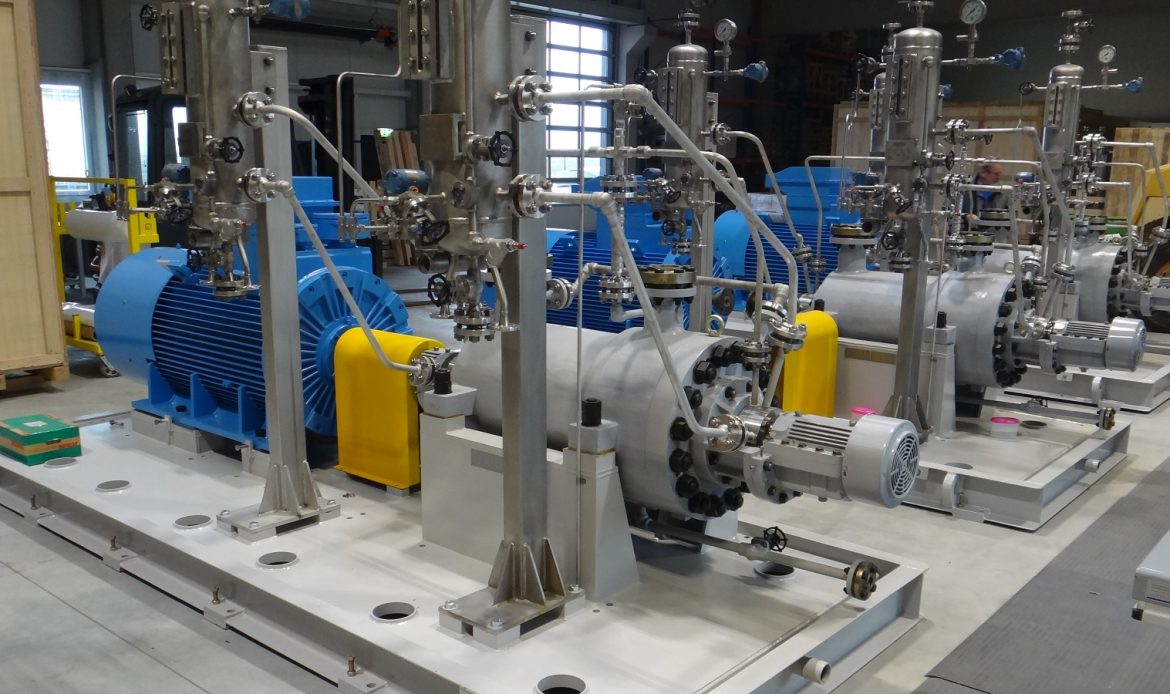

Therefore, what we’d recommend is to start with high-value, failure-prone equipment like motors, pumps, compressors, or generators.

Step 2: Measure Relevant Parameters

Now that you have selected the assets, next crucial step is to identify key performance indicators to monitor. That said, some of the common parameters usually include:

- Vibration: Did you know that abnormal patterns often signal misalignment or bearing wear?

- Temperature: Ah, very important point to consider. Overheating can indicate lubrication issues or electrical faults.

- Current/Power Quality: Fluctuations may reveal motor winding problems.

- Pressure/Flow Rates: Critical for hydraulic systems or pipelines

Now when it comes to collecting this valuable data for condition-based monitoring, you should use sensors, IoT devices, or portable tools. Case in point are the vibration sensors that can be installed on motors. Or you can install thermal cameras for periodic inspections.

Step 3: Analyze the Data

What can you do with just raw data? Well, nothing. This is why you need to use analytics tools that can help transform raw data into valuable insights. For instance, you’ll have to track parameter changes over time as they will help identify degradation patterns. Then there is advanced algorithms that can help detect anomalies human eye cannot detect. Oh and how can we forget about setting the limits for normal operation like the temperature to trigger an alert?

By the way, software programs like the Artesis Enterprise Server (AES) can aggregate data from multiple sources to provide dashboards and predictive insights. For example, a sudden spike in motor current could indicate an impending rotor bar failure, prompting immediate inspection.

Step 4. Create support within the organization

Implementing this may sound simple but it is not possible without making changes to how your team operates. Make sure that you include everyone from the team into the implementation to reap the full benefits. For instance, you should take into account the maintenance manager’s perspective on the matter and guide them on how condition-based monitoring can help ensure the resources are used more efficiently. A production manager can understand how condition-based maintenance can help reduce downtime events.

Step 5: Continuously Improve

We have said this to numerous clients that CMB is not a “set and forget” system. It requires you to refine your approach for better results. For instance, you can reap more benefits by reviewing historical data to adjust thresholds and parameters. Or you can train staff to interpret alerts and use new tools.

The bottom line is that you can incorporate feedback loops to make sure the CMB strategy starts to evolve with your operational needs. That should be goal of your organization.

Want Help?

We are here to support your CBM journey. And for that, we offers a suite of intelligent solutions, including the Motor Condition Monitor (e-MCM), Plant Condition Monitor (e-PCM), Portable Motor-Driven Test System (AMT Pro), and the Artesis Enterprise Server (AES) software. Contact Artesis today to explore how their condition monitoring technologies can transform your operations.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ