Condition-Based Maintenance Strategy in 5 Steps

Choosing the right maintenance strategy is essential for improved reliability and availability of rotating equipment for more sustainable and profitable production. Especially with the impact of digitalization..

Condition Monitoring for Submersible Pumps

Condition monitoring poses a real challenge for hard-to-access equipment such as submersible pumps. It is crucial to use innovative and safe methods to monitor these pumps, which..

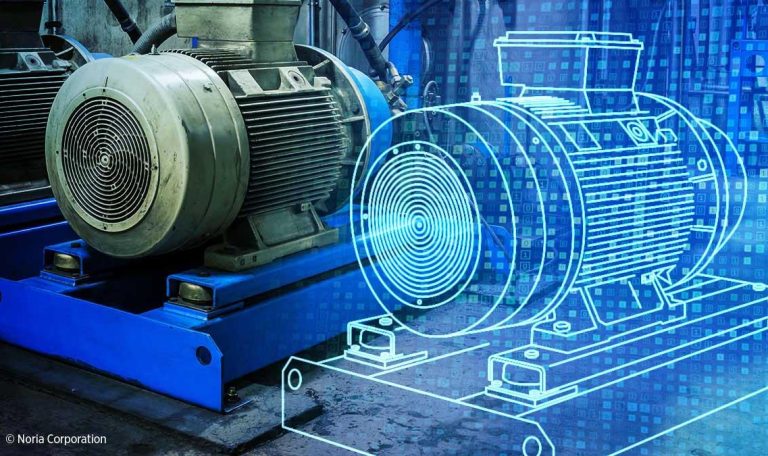

5 Common Faults In Electric Motors

Electrical motors are excellent tools utilized in various ways, making things more straightforward in our daily lives and a broad range of industrial applications. However, when these..

Webinar Series | Condition Monitoring and Fault Diagnostics of Rotating Equipment

Expand your Model-Based Voltage and Current Signature Analysis knowledge through this series of technical presentations, product demonstrations, and collaborative sessions with experts. Join us for the first session of the..

The Role of An Industrial Maintenance Manager In 2022

Industrial organizations are undergoing a rapid digital change era, with increasing interest in data collection and IoT to enable them to make better choices more quickly and..

The Bright Future of Predictive Maintenance

Predictive maintenance is expected to rise rapidly in the following years due to the pressing need to extend the lifespan of aging industrial machinery. Predictive maintenance has..

Key Predictive Maintenance Trends for 2023 and Beyond

Predictive maintenance is a technique that uses data and analytics to predict when equipment is likely to fail, allowing maintenance to be scheduled in advance and improving..

Top Manufacturing Trends for 2023

Manufacturing is an ever-evolving industry, with new technologies and trends always emerging. In 2023, we can expect to see several significant developments that will shape the way..

Avoiding the Challenges of Predictive Maintenance

Predictive maintenance (PdM) is a technique that uses data analytics and machine learning to foresee problems with equipment before they occur. The PdM allows companies to take..

Predictive Maintenance and Asset Management

There is no denying that digitalizing predictive maintenance has many benefits, and one such advantage is the improvement of asset management. After all, digital technologies allow enterprises to achieve..

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ