Artesis Omnisight:

Enterprise Asset Intelligence

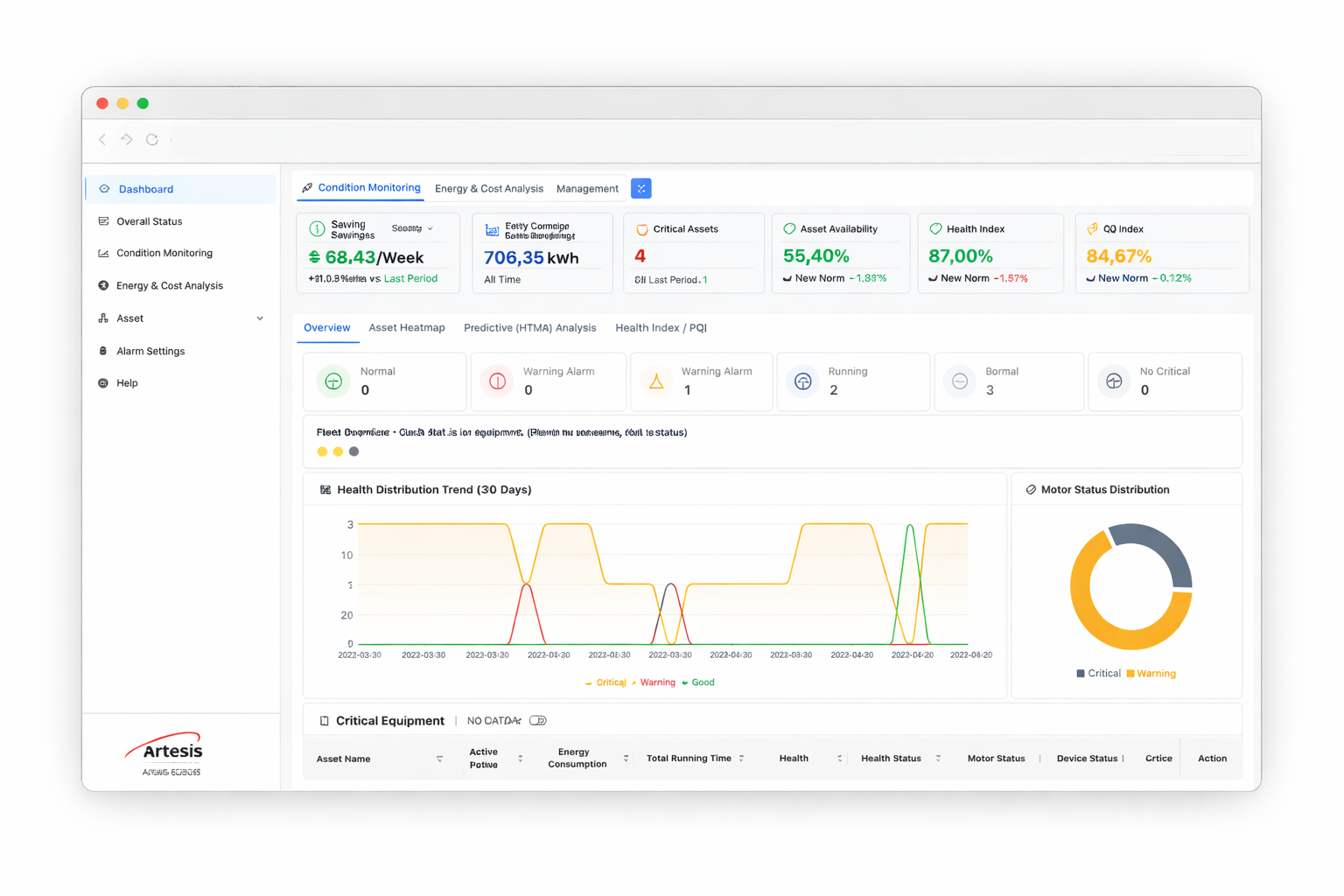

Artesis Omnisight:

Enterprise Asset Intelligence

Unified Visibility Across Your Rotating Assets

Omnisight is Artesis’ integrated platform for asset condition and energy intelligence — providing a single view across critical and non-critical equipment, powered by electrical data and expert insight.

The Visibility Gaps You Face Today

Most organizations struggle with fragmented monitoring approaches that leave critical blind spots.

Fragmented Tools

Multiple disconnected systems for different asset types create data silos and incomplete pictures.

Blind Spots

Non-critical assets often go unmonitored, leading to unexpected failures and hidden energy waste.

Data Without Meaning

Raw measurements without interpretation leave teams guessing about what actions to take.

From Electrical Data to Informed Decisions

A clear pathway from measurement to action, grounded in evidence.

Electrical Data

Continuous and portable data collection from motors via current and voltage signals.

ESA-Based Analysis

Electrical Signature Analysis extracts meaningful indicators from signal patterns.

Artesis Insight™

Plain-language interpretation that explains what the data means for your equipment.

Human Decisions

Actionable recommendations that support your team's maintenance decisions.

Choose How You Monitor

Flexible deployment options unified in a single view.

eMCM — Motor Condition Monitoring Continuous

Permanent monitoring for critical motors with real-time electrical signature analysis.

- 24/7 automated data collection

- Trend analysis over time

- Immediate anomaly detection

- Mission-critical asset focus

ePCM — Generator Condition Monitoring Continuous

Permanent monitoring for generators using electrical signature analysis of power output.

- Generator health indicators

- Electrical anomaly detection

- Trend analysis over time

- Critical power asset focus

AMTPro — Walk-Around Portable

Portable testing for broader asset coverage using the same proven ESA methodology.

- Extend coverage economically

- Same analysis depth

- Unified data in Omnisight

- Non-critical asset visibility

Interpretation, Not Just Information

Flexible deployment options unified in a single view.

Contextual Explanation

Understand what the indicators mean for your specific equipment and operation.

Decision Support

Clear recommendations that support — not replace — your maintenance judgment.

Evidence-Based

Every insight is traceable to measured data, not assumptions or predictions.

Bearing wear indicators show gradual progression consistent with normal degradation. Current levels suggest approximately 3–4 months before recommended inspection. No immediate action required.

A Clear Path to Evidence

Our 60-day pilot program demonstrates value before commitment.

Scope & Setup

Select pilot assets, install monitoring, establish baselines.

Data Collection

60 days of continuous monitoring with regular check-ins.

Review & Learn

Bi-weekly reviews to discuss findings and build understanding.

Evidence & Next Steps

Documented outcomes and clear expansion roadmap.

Built for Rotating Assets

Omnisight monitors the equipment that keeps your operation running.

Pumps

Centrifugal & positive displacement

Compressors

Screw, reciprocating & centrifugal

Fans & Blowers

Axial & centrifugal

Conveyors

Belt, screw & chain drives

Motors

AC induction & synchronous

Mixers & Agitators

Industrial process equipment

Gearboxes

Speed reducers & increasers

Crushers & Mills

Size reduction equipment

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ