Condition Monitoring without Sensors

- Intelligent Fault Diagnosis

- AI-Driven Digital Twin

- Comprehensive Fault Coverage

- Pump Performance monitoring & Cost Analysis

The Artesis e-MCM excels in sensorless monitoring and diagnosing a wide range of faults, providing unparalleled insight into the health of your rotating assets. Utilizing a patented True Machine Learning algorithm and a Model Base with over 10 million fault signatures, the e-MCM performs continuous real-time analysis of voltage and current, detecting mechanical,electrical and process-related faults up to six months in advance,giving you the foresight to address potential issues before they escalate into costly problems.

Developed with NASA technology and backed by over 35 years of R&D and a 25-year successful track record, the e-MCM ensures reliable and cutting-edge condition monitoring, making it an indispensable tool for maintaining the health and efficiency of your rotating assets. Now featuring Pump Performance Monitoring and Efficiency & Cost Analysis, e-MCM takes condition monitoring to the next level, delivering actionable, data-driven insights that translate into tangible operational and energy savings.

Key Features

We’ve redefined motor condition monitoring with a solution that combines fault detection, pump performance tracking, energy efficiency insights, and seamless integration into your existing systems.

Intelligent & Comprehensive Fault Diagnosis

The intelligent fault diagnosis feature of e-MCM makes it very simple to use by the maintenance personnel. Rather than overwhelming the end-user with raw signals and data, e-MCM provides processed data results in an actionable form.

Utilizing a database of over 10 million fault signatures, e-MCM detects and diagnoses issues up to 6 months in advance, ensuring prompt intervention.

- Mechanical Faults: Loose foundation, unbalance & misalignment, belt, gearbox, bearing, impeller, fan blade and more..

- Electrical Faults: Stator, rotor, winding isolation, power quality ,power circuit and more..

- Process Issues: Cavitation, clogging, overload, low efficiency, plugged filters, flow turbulence and more..

- Smart Flow & Pressure Estimation: Utilizes advanced algorithms to accurately estimate flow and pressure using only motor power data—no external sensors required.

- External Sensor Integration: Seamlessly integrates with external flow and pressure sensors if available, enhancing monitoring precision and data depth.

- Duty Point Tracking: Continuously monitors the pump’s duty point, highlighting deviations from the Best Efficiency Point (BEP) to maintain optimal performance.

- Automatic Condition Diagnosis: Automatically diagnoses pump operating conditions, delivering specific insights that enable operators to take timely and informed actions.

- Energy Efficiency Optimization: Identifies inefficiencies and optimizes pump operations to enhance energy usage, reducing overall operational costs and improving sustainability.

Pump Performance Monitoring

Energy Efficiency & Cost Analysis

Energy usage is one of the largest operating expenses in any facility with extensive motor-driven systems. e-MCM’s Efficiency & Cost Analysis module transforms raw current and voltage data into actionable financial metrics:

- Inefficiency Detection: Identify inefficiencies caused by faults, mechanical wear, or process issues.

- Real-Time Energy Savings Metrics: Provide real-time energy savings metrics, helping reduce operational costs.

- Energy Consumption Optimization: Optimize motor and pump operations for minimal energy consumption. By addressing inefficiencies, e-MCM not only reduces costs but also contributes to sustainability goals.

- Optimal Motor Sizing & Efficiency Recommendations: Utilizing its extensive database, e-MCM suggests the ideal motor size and efficiency class for your specific application, providing the essential data needed to accurately calculate ROI..

AI-Driven Digital Twin

- Self-Learning Phase: Utilizes advanced system identification algorithms to build a robust mathematical model, capturing normal machine behavior across various load and speed conditions.

- Real-Time Data Comparison: Continuously measures motor voltages and currents, matching them against the digital twin to detect even subtle deviations from normal operation.

- Minimized False Alarms: Recognizes different operating states—like varying loads or speeds—to avoid unnecessary alerts while maintaining tight fault detection accuracy.

- Full Machine Train Coverage: Identifies and diagnoses issues not just in the motor, but also in the drive train and connected equipment, using the motor itself as a sensor.

- Intuitive Traffic Light Interface: Provides clear indications of fault severity (green, orange, red), alongside estimated time-to-failure and recommended corrective actions.

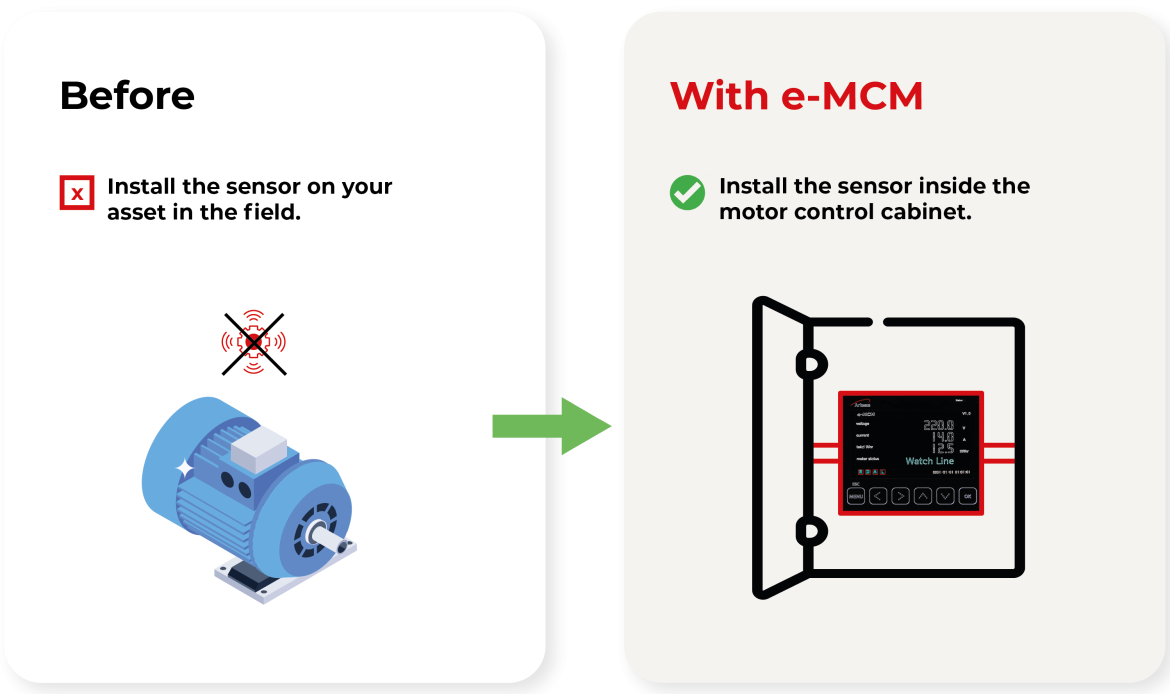

Simplified Installation & Integration

A key benefit of e-MCM is its ease of installation and integration. Because it relies solely on motor current and voltage readings, e-MCM:

- Requires Minimal Hardware: No invasive sensor mounting or modifications to existing machinery are necessary.

- No Size or Voltage Limitations: e-MCM is compatible with all motor-driven systems, regardless of size or voltage, making it ideal for any application.

- Seamless Integration with Existing Systems: Effortlessly connects to SCADA, DCS, and other plant control systems using standard industrial communication protocols.

- Features a User-Friendly Interface: Delivers intuitive dashboards for real-time monitoring, fault alarms, and trending.

Malfunctioning AC motors and rotating equipment are draining your time and resources.

Unplanned equipment failures can disrupt operations and drive up costs. Malfunctioning AC motors and rotating equipment lead to costly downtime, delays, overtime expenses, and even safety risks for your maintenance team. Proactively planning maintenance before failures occur helps you save time, reduce expenses, and ensure a safer workplace.

How it works

- Connect eMCM to the motor’s electrical supply.

- The system creates a digital twin through self-learning.

- Continuously monitors voltage and current data.

- Detects faults and provides actionable insights in real time.

- Tracks pump performance metrics like flow and head for operational excellence.

Artesis e-MCM Video

Artesis: Empowering Industrial Excellence Through Advanced Solutions

Water

Water

Oil & Gas

Oil & Gas

Automotive

Artesis and Jacobs Engineering Successfully Resolve Capacitive Coupling Issue

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ