It’s interesting how the global predictive maintenance market is growing. In 2022 alone, it grew to $5.5 billion and there is forecast that it will keep growing at a compound annual growth rate (CAGR) of 29.5% to the end of this decade.

These insane numbers make sense since predicative maintenance delivers substantial advantages across diverse industries. By bolstering equipment reliability, minimizing downtime, and trimming maintenance costs, it proves invaluable. In the manufacturing sector, these practices play a pivotal role in averting unforeseen breakdowns and optimizing production schedules, contributing significantly to operational efficiency.

So let’s explore the emerging trends in maintenance for 2024 and understand the crucial importance of staying ahead with these developments, ensuring you don’t miss out on valuable opportunities.

Contents

Maintenance as a Service (MaaS)

Embracing a subscription-based outsourcing model, businesses can efficiently delegate the management and maintenance of their assets to dedicated service providers. The Maintenance as a Service (MaaS) model proves instrumental in streamlining maintenance processes, curbing costs, and enhancing overall asset performance.

As we look ahead, it’s evident that the influence of cloud computing and cloud-based business models is poised to disrupt the landscape of industrial maintenance, marking a significant shift in how organizations approach and optimize their asset management strategies. Therefore, this is certainly a maintenance trend not to miss.

Artificial Intelligence

In today’s fast-paced world of technology, artificial intelligence is making a big impact on how we handle predictive maintenance. It’s not just for manufacturing; AI plays a crucial role in improving production and is becoming key in the next phase. Beyond that, it’s also helping to keep our organizations safe through enhanced security systems.

Moreover, there’s the collective use of AI and machine learning to make predictive maintenance smarter. They analyze data automatically, spot issues early on, and make accurate predictions. They also help figure out the best times for maintenance tasks, offer support in decision-making, and keep getting better at what they do. This collaboration doesn’t just improve maintenance; it makes AI a trend not to miss in the ongoing development of how industries operate.

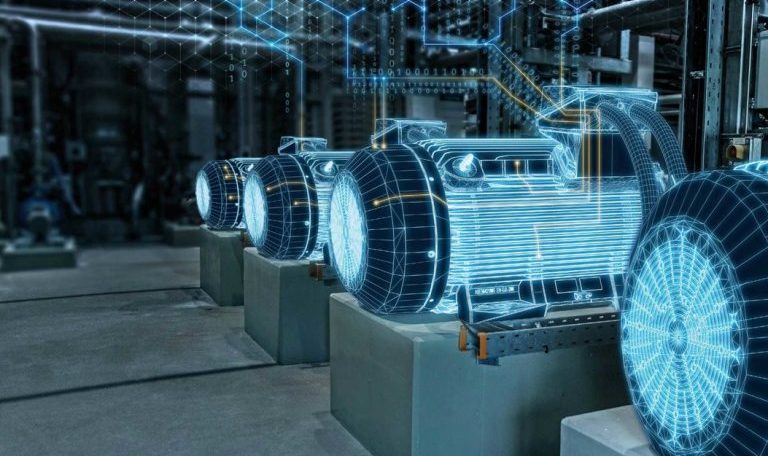

Immersive Technologies Like Augmented Reality (AR)

Enter the future of maintenance efficiency with Augmented Reality (AR), a game-changer that turbocharges machine maintenance, ensuring swifter processes and minimal errors. Serving as a real-time guide for both on-site and remote maintenance teams, AR emerges as a disruptive force in the maintenance tech arena. Forget lengthy training sessions and complicated manuals—AR simplifies the game. Maintenance staff can effortlessly follow visual cues in real-time, eliminating the need for extensive training or complex instructional gear.

Additionally, utilizing AR-powered headsets or wearables enables teams to access 3D models of intricate equipment, swiftly identify components, and resolve issues with precision. AR is not just a tool; it’s the future of smart, efficient maintenance practices.

Industrial Internet of Things

In the world of automated Industrial Internet of Things (IIoT)-driven predictive maintenance systems, sensors play a pivotal role in assessing a machine’s operational health. These sophisticated sensors adeptly detect issues like temperature fluctuations, irregular vibrations, and wear patterns on components.

By utilizing internal sensors, these systems continuously gather real-time data from machinery, enabling the anticipation of potential equipment failure before it manifests. Recognizing the symbiotic relationship between sensors and predictive maintenance is paramount, considering that sensors stand out as the most reliable source of data—a trend poised to dominate in 2024.

Decentralized Repair Teams

The emerging trend of decentralized repair teams is reshaping the landscape of maintenance practices. Traditionally, maintenance teams operated within centralized structures, often tied to a specific location. However, the decentralization wave is gaining momentum, and maintenance is no exception. Decentralized repair teams entail distributing maintenance personnel across various locations, allowing them to respond swiftly to issues without being restricted by geographical constraints.

This approach not only enhances the agility of maintenance responses but also taps into the expertise available in diverse locations. Through leveraging technology, such as augmented reality for remote guidance and real-time collaboration tools, these decentralized teams can efficiently diagnose, troubleshoot, and address maintenance issues with speed and precision.

We hope that this piece provided you the information you needed. If you want to know more about predictive maintenance, please feel free to contact us. We look forward to hearing from you.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ