Sensorless Pump Performance Monitoring

- Real-Time Duty Point and Efficiency Tracking

- Sensor-Free Flow and Head Monitoring

- Optional Sensor Integration

Empowering Smarter Pump Monitoring

e-MCM is not just a condition monitoring tool—it's your gateway to advanced pump monitoring without the need for additional sensors. Using eMCM's intelligent algorithms, you can track pump flow, head, and operating efficiency in real time, ensuring optimal performance and reliability.

eMCM’s Pump Monitoring Feature

Sensor-Free Flow and Head Monitoring

e-MCM uses only voltage and current data to calculate critical pump performance metrics such as flow and pressure head. This sensor-free approach simplifies setup, reduces costs, and minimizes hardware maintenance.

Real-Time Duty Point and Efficiency Tracking

• Monitor your pump’s duty point on the pump curve in real time.

• Ensure your pump operates near its Best Efficiency Point (BEP) for maximum energy efficiency and reliability.

• Receive immediate alerts when your pump deviates from the optimal operating range.

• Ensure your pump operates near its Best Efficiency Point (BEP) for maximum energy efficiency and reliability.

• Receive immediate alerts when your pump deviates from the optimal operating range.

Optional Sensor Integration

If your system includes flow or pressure sensors, eMCM seamlessly incorporates this data to enhance monitoring precision. This flexibility ensures that e-MCM adapts to your specific needs and infrastructure.

Key Capabilities of e-MCM for Pump Monitoring

Benefits of Pump Monitoring with e-MCM

- Simplified Setup: Sensor-free operation streamlines installation and reduces hardware requirements.

- Optimized Energy Efficiency: Operate at the BEP to minimize energy losses and lower operating costs.

- Reduced Maintenance Costs: Detect faults early to avoid costly breakdowns and repairs.

- Extended Pump Lifespan: Prevent unnecessary wear by ensuring optimal operating conditions.

- Improved Reliability: Continuously monitor pump health to avoid unexpected downtime.

Applications for e-MCM Pump Monitoring

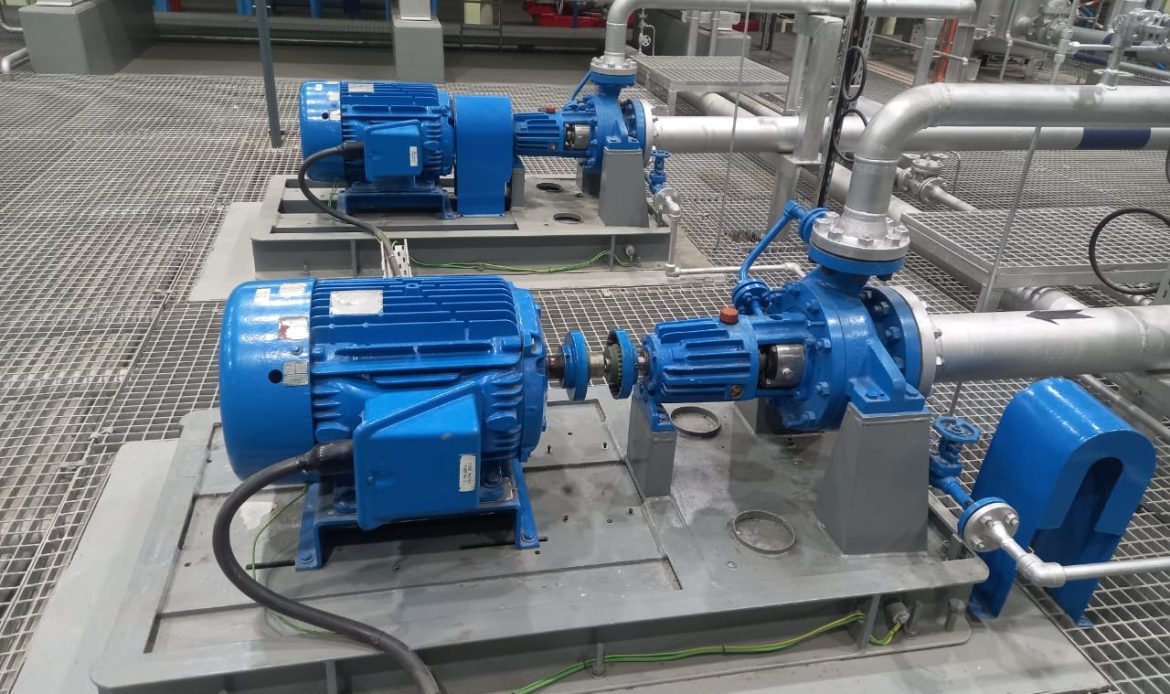

The pump monitoring feature in eMCM is ideal for a wide range of industries, including:

- Water Utilities & Wastewater Treatment

- Oil & Gas

- Food & Beverage

- Pharmaceuticals

- Energy and Power Generation

Whether your pumps are small-scale or industrial-grade, eMCM ensures they perform efficiently and reliably.

Discover the Power of e-MCM

With e-MCM’s pump monitoring feature, you can:

- Monitor flow and head using voltage and current data—no additional sensors needed.

- Track your pump’s position on the pump curve and maintain operation near the Best Efficiency Point.

- Proactively address faults to avoid downtime and improve operational safety.

- Seamlessly integrate with existing flow or pressure sensors for enhanced insights.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ