We all know that today’s demand for vehicles are much more than the ones a few years ago. It is no surprise why the automotive industry is transitioning from preventive maintenance to predictive maintenance. Due to the growing global demand for the automotive predictive maintenance market, it is estimated to reach over US$2.7 billion by 2027. Let’s take a look at the benefits of predictive maintenance and its impact on automotive manufacturing.

Due to the growing global demand for the automotive predictive maintenance market, it is estimated to reach over US$2.7 billion by 2027.

What is Predictive Maintenance?

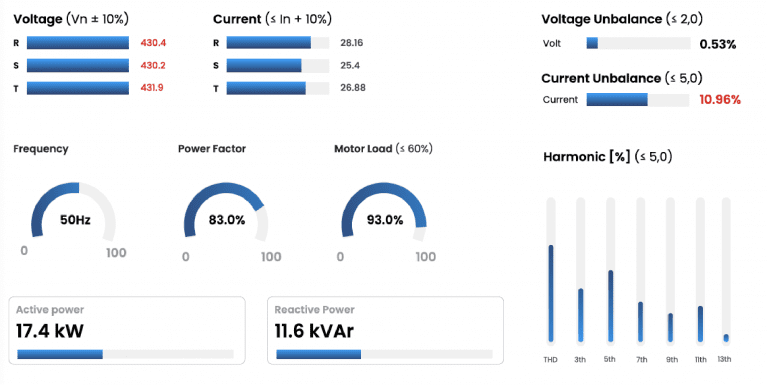

Predictive maintenance can be explained as techniques designed to detect irregularities and defects in the condition of in-service equipment and helps determine when the maintenance should be performed. It is considered a cost-saving technique as it enables you to fix a problem before it results in a failure. Predictive maintenance uses the principles of statistical process control that enables it to assess the equipment and predict when maintenance activities will be appropriate.

Case Study:

How Does Predictive Maintenance Work?

In the automotive industry, predictive maintenance works by first monitoring and analyzing the entire operation. It then gathers and stores the data upon which it makes an important forecast. Overall, the whole process is smooth and without any significant complications.

Benefits of Predictive Maintenance in The Automotive Industry

There was a time when it was considered that predictive maintenance could be relevant to the automotive industry. Now, it is more than just relevant; it has become essential. Given how much value it brings to the table for the automotive industry, it would be a big mistake to say no to it, let alone avoid it.

You can tailor predictive maintenance to your needs, and it can help with:

- Accurately predicting any impending failures

- Asset condition monitoring

- 24/7 monitoring of the equipment

- Mechanical predictive maintenance for reliability

- Quick on-site assessment of motors, pumps, and other rotating equipment

One of the major benefits of predictive maintenance is enhanced security. It plays a pivotal role in ensuring there is no downtime.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ