Online condition monitoring systems form the basis of more digital and manageable maintenance systems. Thanks to online motor condition monitoring, critical equipment can be monitored 24/7 and can be easily intervened when necessary. The global pandemic we have found ourselves in and the trend in digitalization in the past decade have significantly increased the interest in online tools.

We see this not only in our daily life but also in almost every field of industry, ranging from production to maintenance activities. The importance of accessing facilities anytime from anywhere was doubly understood in the pandemic and undeniably online condition monitoring provides serious opportunities to reach data 7/24 to employees who are working remotely. One of the most important factors that contribute to the competitiveness of production facilities today is being able to make sense of the data they collect and take improvement action as a result.

Another important issue is reducing unplanned downtime and maximizing plant availability for maximum production to step forward in the marketplace. Unplanned downtime can cost businesses a couple of hundred thousand $ per hour in the United States alone. In fact, these numbers can reach much higher levels in fields like cement, iron-steel, and automotive industries.

Contents

What is Online Condition Monitoring?

Online Condition monitoring provides a forecast for potential failures and gives the opportunity to corrective actions before failures.

- Minimizes unplanned downtime.

- Extends equipment life.

- Increases facility security.

- Contributes significantly to energy efficiency.

- Provides ease of maintenance planning

- Reduces medium- and long-term maintenance costs.

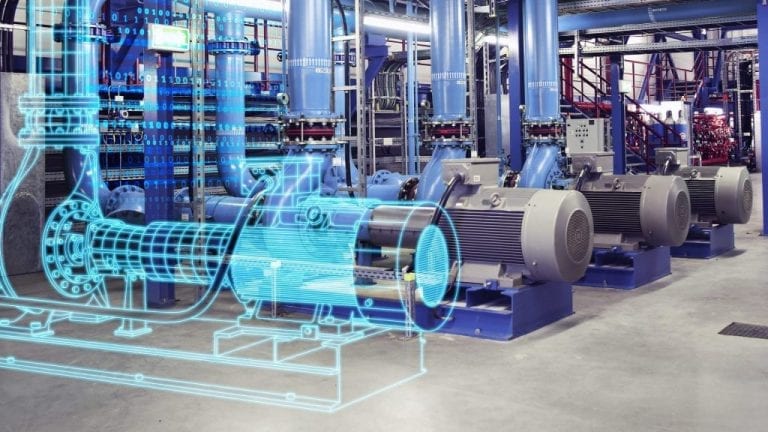

Online condition monitoring systems are a good solution, particularly for facilities that expand over very large areas, that are difficult to access or restricted (such as flammable and explosive areas). Online condition monitoring systems offer a much wider perspective than traditional condition monitoring methods. With the online condition monitoring system, more data is collected with less effort. Equipment abnormalities that may occur are determined much earlier, with more precision.

What are the Advantages of Online Condition Monitoring?

The primary advantage of online condition monitoring is reducing OPEX costs significantly. Since it is an online tool, there is no need for manual on-site data collection, thus reduces the need for manpower in the field. In addition, online condition monitoring is an important stakeholder of the reliable and predictive maintenance process.

Features

- Comprehensive data collection 7/24

- Significant reduction of dependency on staff

- Immediate intervention chance thanks to the dense data flow, especially in critical equipment

- Easy identification of intermittent process errors that affect equipment’s working quality and reduce its efficiency

Difference Between Online and Offline Condition Monitoring

Online condition monitoring systems mean 24/7 monitoring of monitored rotating equipment. Online systems are preferred especially for monitoring critical assets. Offline condition monitoring, on the other hand, can be preferred for the monitoring of more economical and not so critical rotating equipment. The motors selected in the offline system are checked at regular intervals and the onset of malfunction is tried to be diagnosed at an early stage.

However, in online systems, data is constantly monitored and reported to the maintenance team. Any malfunction that may occur is detected with a very high degree of accuracy at the initial stage and immediately reported.

What Artesis Offers in Online Condition Monitoring?

Thanks to its patented technology, Artesis offers smart monitoring solutions for the condition of electric motors, fans, pumps, compressors, and conveyor systems. These solutions detect both mechanical (unbalance, axial misalignment, bearing, etc.) and electrical faults (winding looseness, short circuit, etc.). You can also monitor electrical parameters such as RMS voltage, RMS current, power factor, and harmonic distortion.

Why Artesis e-MCM?

The automated diagnostics feature of e-MCM makes it very easy to use by maintenance personnel. Instead of dealing with raw signals and data, e-MCM empowers the end-user to access the processed data in actionable form. The Artesis online condition monitoring system requires minimal personnel intervention for installation and commissioning while provides both locally and remotely monitored equipment.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ