Electric motors function as silent giants throughout global energy consumption because they use more than 45 percent of worldwide electricity. These workhorses drive everything from manufacturing lines to water treatment facilities, yet they often operate well below their optimal efficiency. The consequences are substantial: inflated energy bills, premature equipment failure, and unnecessary carbon emissions.

Basic inspections combined with reactive maintenance have traditionally been the standard methods for motor management until problems require repair. The outdated approach to maintenance no longer meets the requirements of modern operational excellence and sustainability standards. The industrial sector requires advanced proactive solutions which detect inefficiencies before they become expensive failures.

Contents

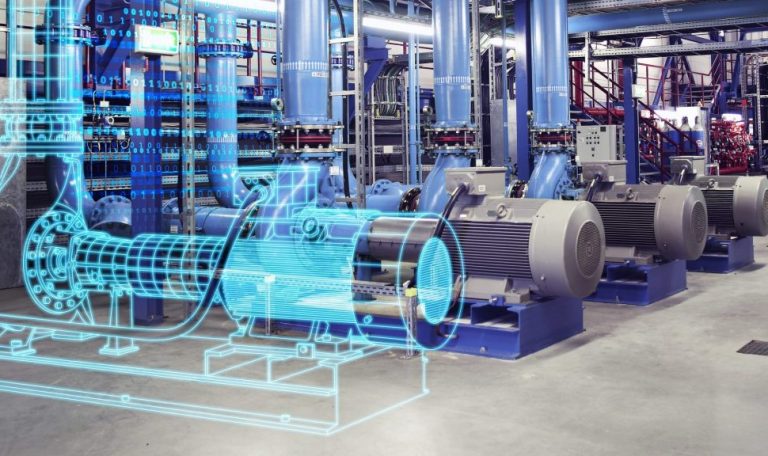

Reimagining Motor Monitoring with Artesis Technology

Artesis has developed an AI-based motor efficiency monitoring system that exceeds traditional monitoring capabilities. You see, the Artesis technology operates as both a protective system and a guidance tool by analyzing motor performance and predicting problems and providing optimization recommendations.

The advanced capability exists because of continuous real-time monitoring operations. Artesis systems provide constant monitoring through their systems which track voltage patterns and current fluctuations and power quality metrics throughout the entire day. The continuous monitoring process allows the system to detect minor anomalies which would normally remain undetected until they become major issues.

The unique selling point of Artesis comes from its advanced machine learning system. The system develops an extensive knowledge of motor operational patterns during its learning phase before it starts monitoring for any deviations from established performance baselines. The system detects bearing wear and rotor bar defects and winding failure precursors before human operators can identify performance changes through weeks or months of monitoring.

More Interested: Online Condition Monitoring e-MCM

Revolutionary Sensor-Free Technology

The most impressive feature of Artesis is its e-MCM (Electronic Motor Condition Monitoring) technology which performs advanced diagnostics without requiring any additional sensors. The conventional monitoring systems need extensive installation of vibration sensors and temperature probes and other hardware throughout a facility yet e-MCM analyzes electrical signals from the motor power supply.

The sensor-free monitoring system makes installation easier and decreases both setup expenses and upkeep needs. The system allows businesses to monitor their facilities at scale without the high costs and complicated sensor network setup.

Motor Efficiency with Seamless Integration into Existing Infrastructure

Artesis has developed its solutions to work seamlessly with existing systems because it recognizes that industrial facilities require significant technological investments. The technology integrates seamlessly with SCADA networks and maintenance management software and IoT platforms to provide these systems with enhanced motor performance insights.

The system maintains compatibility with standard tools which allows maintenance teams to work with familiar tools while benefiting from Artesis’ advanced diagnostic capabilities. The system enables better decision-making through its integration with existing workflows without requiring any workflow disruptions.

Tangible Benefits Across Industries

The implementation of Artesis technology creates widespread effects which affect different industrial operations that handle distinct operational hurdles. The system operates in manufacturing plants to identify motor problems before they stop production lines thus preventing costly interruptions. Water treatment facilities achieve better pumping system reliability through Artesis technology that both reduces service interruptions and decreases energy requirements for aeration and filtration processes.

The detection system of Artesis technology serves as an essential safety feature for motor operations in dangerous oil and gas environments because it provides early warnings which prevent dangerous equipment failures. The system operates in power generation facilities to ensure steady cooling system and auxiliary equipment performance thus supporting power grid stability and operational effectiveness.

All application users have recorded energy savings of 5 percent to 20 percent – which eventually leads to major cost savings in energy-intensive operations. Motors equipped with Artesis technology monitoring systems live longer than unmonitored motors by 20-30 percent which extends replacement periods and minimizes overall operational expenses.

More Interested: Predictive Maintenance And Asset Management

The Future of Industrial Efficiency

The rising energy costs along with escalating sustainability requirements have made motor efficiency optimization transform from a competitive tool to an essential business requirement. As an industrial leader Artesis leads the transformation with its distinctive blend of artificial intelligence and practical engineering expertise and user-focused design.

Organizations gain simultaneous benefits of cost reduction and equipment life extension while preventing unexpected downtimes and minimizing environmental effects through this technology. The system addresses all current challenges in modern industrial operations which include immediate financial requirements together with extended sustainability targets.

Our intelligent motor monitoring provides more than improved traditional methods since it represents a complete revolution in essential equipment management for industries. The industrial future of manufacturing and processing operations depends on Artesis technology to drive motors at their maximum potential through continuous advancement towards increased automation and efficiency.

Trust the revolution – after all, more than 500+ global brands run on Artesis and we are expanding at an exponential rate.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ