Why Sensorless Technology is the Future of Predictive Maintenance

The modern industrial environment identifies downtime as the ultimate productivity destroyer. That’s why the industrial sector now uses predictive maintenance to detect equipment failures before operational disruptions..

How to Maximize Electric Motor Reliability and Life – 5 Must Know Tips

Multiple industrial operations utilize electric motors to operate their production lines together with their heavy machinery equipment. Motor reliability combined with extended lifespan helps companies avoid major..

Mastering Condition-Based Maintenance: A 5-Step Implementation Guide

There is absolutely no denying the fact that condition-based maintenance (CBM) is playing a pivotal role in revolutionizing one important thing. Any guesses? Well, it is reshaping..

Enhancing Hot Strip Mill Reliability with Advanced Condition Monitoring

One thing can be said with certainty that hot strip mills are the backbone of steel production as they operate under extreme conditions to transform slabs into..

5 Reasons To Use AMT Pro in Your Factory Immediately

In today’s fast-paced industrial world, the need for efficient, reliable, and smart maintenance solutions has never been more critical. With the introduction of the Artesis AMT Pro, factories..

Best Key Performance Indicators for Every Industrial Maintenance Team

Navigating the complex world of industrial maintenance can feel like trying to solve a giant puzzle. Every piece needs to fit perfectly for the machinery to run..

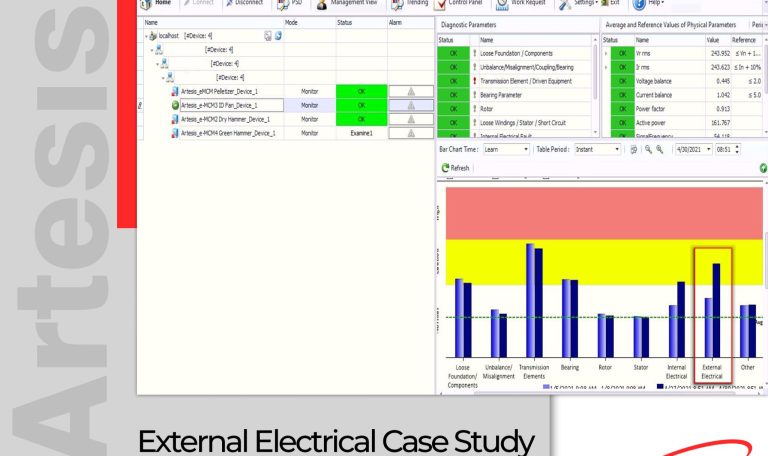

Case Study Electrical Faults Connection Looseness

When monitoring the condition of rotating equipment, one of the easily overlooked problems is electrical connection looseness. The Artesis e-MCM has detected the loose wire connections on..

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ