In today’s fast-paced industrial environment, ensuring the optimal performance and longevity of critical equipment is of paramount importance. And with the advent of advanced technologies, condition monitoring and predictive maintenance tools have become indispensable. For instance, one such cutting-edge tool is the Artesis e-MCM, an online condition monitoring, predictive maintenance, and power meter tool designed specifically for critical AC rotating equipment. Here are five compelling reasons why you should consider integrating e-MCM into your maintenance strategy

Contents

1) Proactive Fault Detection

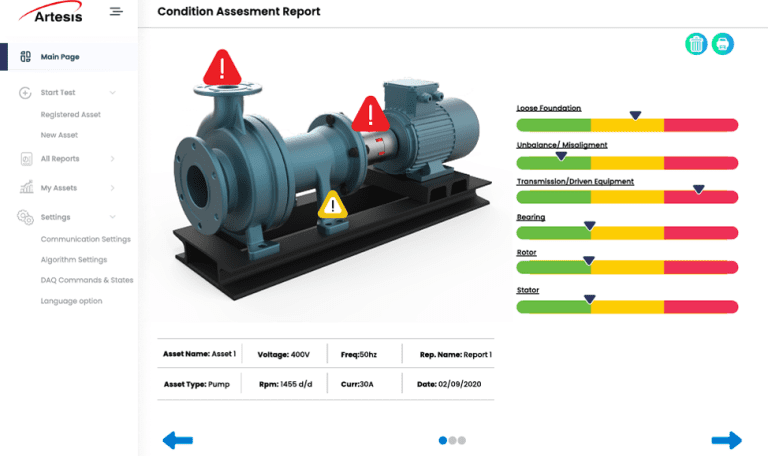

One of the standout features of the Artesis e-MCM is its ability to detect faults up to six months in advance. Utilizing a patented machine learning algorithm, e-MCM continuously monitors the condition of your equipment, identifying potential issues long before they lead to significant failures. This proactive approach allows maintenance teams to address problems early, reducing the risk of unexpected downtime and costly repairs.

Traditional maintenance methods often rely on reactive measures, addressing issues only after they have caused significant damage. In contrast, e-MCM’s predictive maintenance capabilities enable you to plan and schedule maintenance activities at the most convenient times, minimizing disruptions to your operations.

2) Comprehensive Monitoring Capabilities

The e-MCM is not just a predictive maintenance tool; it also serves as a powerful online condition monitoring system and power meter. It provides real-time data on various parameters of your AC rotating equipment, including vibration levels, temperature, and power consumption. This comprehensive monitoring capability ensures that you have a holistic view of your equipment’s health and performance.

By continuously tracking these critical parameters, e-MCM helps you identify inefficiencies and areas for improvement. For instance, abnormal vibration levels can indicate mechanical imbalances, while excessive power consumption might suggest electrical issues. Addressing these problems promptly can lead to significant energy savings and improved equipment lifespan.

3) Enhanced Reliability and Safety

Equipment reliability and safety are paramount in any industrial setting. The e-MCM enhances both by providing early warnings of potential failures, allowing for timely interventions. This early detection of issues not only prevents unexpected breakdowns but also reduces the risk of accidents caused by equipment malfunction.

In industries where equipment failure can have severe consequences, such as manufacturing, oil and gas, and power generation, ensuring the reliability and safety of machinery is crucial. The e-MCM’s ability to predict and prevent failures enhances the overall safety of your operations, protecting both your workforce and your investment

Best Key Performance Indicators For Every Industrial Maintenance Team

4) Cost-Effective Maintenance Management

Implementing e-MCM can lead to significant cost savings in your maintenance operations. By shifting from a reactive to a predictive maintenance approach, you can reduce the frequency and severity of repairs. This not only lowers maintenance costs but also extends the lifespan of your equipment.

The data provided by e-MCM allows you to optimize your maintenance schedule, ensuring that maintenance activities are performed only when necessary. This targeted approach eliminates unnecessary maintenance tasks, further reducing costs and minimizing downtime. Additionally, early detection of issues means that repairs can often be simpler and less expensive than addressing major failures.

5) Easy Integration and Scalability

The Artesis e-MCM is designed for easy integration into your existing infrastructure. Its user-friendly interface and straightforward installation process mean that you can quickly start reaping the benefits of advanced condition monitoring and predictive maintenance. The system is compatible with a wide range of AC rotating equipment, making it a versatile solution for various industrial applications.

Furthermore, e-MCM is scalable, allowing you to expand its use as your operations grow. Whether you need to monitor a single piece of equipment or an entire fleet, e-MCM can accommodate your needs. Its scalability ensures that you can continue to rely on it as your business evolves, making it a long-term solution for your maintenance strategy.

The Key Takeaway

The Artesis e-MCM offers a powerful and versatile solution for condition monitoring and predictive maintenance of critical AC rotating equipment. Its ability to detect faults up to six months in advance, comprehensive monitoring capabilities, enhancement of equipment reliability and safety, cost-effective maintenance management, and easy integration and scalability make it an invaluable tool for any industrial operation. By adopting e-MCM, you can ensure the optimal performance, longevity, and safety of your equipment, ultimately leading to improved operational efficiency and reduced maintenance costs. Invest in e-MCM today and take a proactive approach to maintaining your critical assets.

White Papers

White Papers Case Study

Case Study Documents

Documents Webinars

Webinars Events

Events ROI Calculator

ROI Calculator FAQ

FAQ